Table of Contents

- What is Bicycle Belt Drive?

- Why Are Belt Drive Bikes Better Than Chain Drive Bikes?

- Why Don’t We See Belt Drive On More Bikes?

- General FAQ

- How do belts feel to ride?

- Why don’t they use belt drive bikes in the Tour de France?

- Don’t automotive timing chains last longer than timing belts?

- How expensive are belt drive bikes?

- Can you use belt drive with eBikes?

- Can you use belt drive in the mud and snow?

- Can you use belt drive on fixed gear bikes?

- Can you use belt drive with full suspension bikes?

- Do belts ever snap?

- Do vandals cut belts?

- How expensive are belt drive components?

- Aren’t there limited gear ratios available on belt drive bikes?

- Can you modify a frame for belt drive?

- Maintenance FAQ

- Gates Carbon Drive Components

- Performance

- Are belt drive bikes worth it?

Belts are used to run the blowers on 10,000 horsepower racing engines, the powertrains of 150 horsepower motorbikes, and more recently, the drivetrains of many bicycles.

I’ve been an avid user of belt drivetrains on my bikes for about 12 years now, and have somehow clocked over 135,000km (~88,000 miles) on these chain alternatives.

I’ve taken belt drivetrains up the world’s highest roads, across dry deserts, through wild jungles, along windy beaches, over monstrous salt flats, and into epic snowscapes.

In this article, I’ll tell you why belt drive is better than chain drive for many cycling applications. I’ll then explain why you don’t see belt drive on more bikes. And lastly, I’ll comprehensively answer every question I’ve ever received about these drivetrains.

Throughout this article, keep in mind I’m referring to my experience with one specific product – Gates Carbon Drive CDX. But this is not a sponsored article and I have no affiliation with Gates. If I come across as enthusiastic it’s simply because I’m a happy customer.

Let’s start with the characteristics of bicycle belt drive.

What is Bicycle Belt Drive?

A bicycle belt is different from all other types of belt. They are constructed from a polymer that is reinforced using multiple carbon fibre cords.

It’s these tensile cords that make them especially strong; Rob Rast from FLX bikes shows that you can even lift up the back of a van without breaking a bicycle belt.

These belts are usually paired with steel rear sprockets and alloy front sprockets, and can be run single-speed, or multi-speed when paired with a gearbox or internal gear hub.

Why Are Belt Drive Bikes Better Than Chain Drive Bikes?

Firstly, belts are very long-lasting. Most cyclists go years without needing to replace a belt or sprocket. I’ve recently put 35,000km (22,000mi) into a belt drivetrain that saw many steep hills and every riding condition possible. Others have even exceeded 40,000km. This is often three to four times further than you can travel with a chain.

Belts are also very low maintenance. This is because they don’t require any grease or lubrication, and much less cleaning too. Just a splash of water is often it.

Due to the lack of grease and oil, belts stay very clean. This means you’ll never get black muck on your hands or pants ever again.

Belts also run eerily silent. Normally, all you can hear is a light hum coming from your drivetrain.

Belts are particularly good in adverse conditions. This is partly due to the sprocket design, which can very effectively shed debris from its surfaces, unlike a chain. But it’s also because you will likely be pairing your belt with a gearbox drivetrain, which keeps your critical drive components sealed away and protected from the elements.

Belts do not rust. This is advantageous at the beach or in cold parts of the world where salt is put on the roads.

Ultimately, belts save you a lot of time. Most people don’t like maintaining their bikes, sourcing replacement parts, or going to bike shops for repairs. Belted bikes minimise all of these things so you can spend more time learning about bikes on CyclingAbout!

If belts are so good, why don’t we see them on more bikes?

Why Don’t We See Belt Drive On More Bikes?

The biggest downside is that belts are not compatible with derailleur gears. This means you need to use a gearbox or internal gear hub for the gears.

Now, I love gearboxes and think they’re perfect for hard-working cargo, commuter, and touring bikes. Gearboxes are strong, reliable, low maintenance, less susceptible to damage, and you can even change gears while stationary.

But gearboxes are also often one kilogram heavier, and 5% less efficient than derailleur gears. They also don’t shift that well under load. So, if you want the lightest or fastest bike, it won’t be sporting a belt.

Belts also require a special frame. These frames must have a way to adjust the tension, they must have a split in the rear triangle to install a one-piece belt, and they must have an especially stiff rear triangle so that the belt cannot skip on the rear sprocket.

Belts are often not found in bike shops. This means that you will need to order replacements online – it’s obviously best to do this before you need them.

Belt components have a higher upfront cost. A new CDX drivetrain is around US $250 or €250. But keep in mind the cost-per-kilometre can be similar to a high-performance chain drivetrain due to the longer wear life.

Belts cannot be repaired. This means that if you damage your belt – it will need to be replaced. The good news is that broken belts are uncommon (I’ve only ever broken one) but you should still carry a spare on long rides. They coil up small and weigh under 100 grams, which is about the same weight as the chain breaker tool that you can now leave at home.

Let’s now move on to the questions, which will get more technical as we go.

General FAQ

How do belts feel to ride?

They feel like an even smoother version of a well-lubricated chain. Despite the way they look, there is no noticeable ‘stretch’ in the belt thanks to the carbon fibre tensile cords that are hidden inside.

Why don’t they use belt drive bikes in the Tour de France?

To compete at the highest level of cycling, it’s necessary for riders to have the lightest and most efficient bikes. Unfortunately, belt drive bikes are heavier and less efficient (as a result of the gearbox), so you’ll never see them in the Tour de France.

Don’t automotive timing chains last longer than timing belts?

This is often true. But keep in mind that belts on bikes are a different application and technology. All durability tests suggest that belts last longer on a bicycle.

How expensive are belt drive bikes?

A belt drive bike with a 3-speed internal gear hub starts at US $599 (Priority Classic Plus). And a bit over €1,000 gets you a bike with an 8-speed hub (Cube Hyde). The prices go well into five figures for fancy e-bikes.

Can you use belt drive with eBikes?

Most belts are approved for eBike use. But in the Gates range, it’s only the CDC and CDX models that will allow for mid-drive motors. There’s a torque limit to be aware of – the lower-cost CDC model is approved for 50Nm motors while CDX is good for 90Nm.

Can you use belt drive in the mud and snow?

I’ve taken my belt drive bikes through thousands of kilometres of mud and snow. But keep in mind it’s only Gates CDX that’s rated for riding in the mud. The models that are rated to shed snow and ice are CDX, CDC, and CDN.

Can you use belt drive on fixed gear bikes?

You can, and it looks pretty rad. Fixed gear belted bikes can be found over at Schindelhauer and Priority.

Can you use belt drive with full suspension bikes?

Yes, a spring-loaded tensioner makes this possible. The tensioner is actually a super cool bit of kit as it accounts for the increasing chainstay length as you get deeper into your travel.

For more, check out bikes by Zerode, Nicolai, Gamux, Riese & Muller, Aska, and Cavalerie.

Do belts ever snap?

They do. The good news is that a broken belt is not a common occurrence and it’s usually preventable (I’ll answer this in more detail in the section “Why do belts break?”).

Do vandals cut belts?

This has never happened to me, and I have never heard of this happening to anyone else.

How expensive are belt drive components?

A replacement drivetrain for my bike costs around US $250, which is a lot, but when you consider that you can travel more than 35,000km for this price – it’s not any different from a high-performance chain drivetrain.

That said, chains can be run cheaper. I’d estimate that Shimano Alfine components work out at half the price on a per-kilometre basis.

You might be enticed by the entry-level Gates SideTrack drivetrain costing just US $100, but it lasts less than half the distance of CDX, resulting in a similar cost per kilometre.

Aren’t there limited gear ratios available on belt drive bikes?

There are lots of gear ratio options these days. You’ll find eight front sprockets, 13 rear sprockets, and 23 belt lengths in the Gates CDX range.

Can you modify a frame for belt drive?

You can, and I’ve actually added belt splitters to multiple frames over the years. Some heavy-duty frames will be well-suited to modification, but for the best user experience, I recommend using a frame that’s engineered with the correct stiffness to use a belt.

If your modified frame turns out to be too flexy, the belt can lose too much tension, and will slip on the rear sprocket. You can combat this with a higher belt tension, but this is less efficient and wears out your sprockets faster.

Maintenance FAQ

What’s the belt maintenance like?

Belt drivetrains are often said to be zero maintenance but I didn’t squeeze 35,000km (22,000mi) out of my drivetrain without a little bit of care.

Debris from the road or trail wears the sprockets down quicker, so make sure to periodically use a toothbrush and a splash of water to remove any grit.

What does a belt drivetrain look like after 35,000km?

The front and rear sprockets are now less than 1mm (1/32″) thick and are sharp to touch. This is approximately 1/3 the thickness of a new sprocket, but I’ve seen sprockets worn down much more than mine.

Do belts ever make noise?

In dry environments with ultra-fine dust, you will likely end up with a squeaky belt. I use treadmill silicone lubricant to keep things quiet. The good thing is that this is not an aerosol, so you can put it in tiny bottles for short adventures.

There is a new product from Universal Transmissions that dries on as a film – I’ll be testing that next. Please avoid the Hanseline belt care stick as it’s very sticky and attracts grit.

How do you set the belt tension?

Unlike chains, belts do not get longer with use, so you won’t need to adjust the tension until the sprockets have worn down significantly.

There are two typical ways to set the tension of a belt. Some bikes use sliding rear dropouts, and others use adjustable eccentric bottom bracket shells (see picture below).

You can use your smartphone to determine the appropriate tension. By plucking the belt, your smartphone app will decipher the frequency and determine if your tension is correct.

That said, I’ve found that frames with especially stiff rear triangles will allow for significantly less belt tension than is recommended by Gates. Make sure you’ve got a ‘belt snubber’ on your bike (which keeps the belt on the rear sprocket), and tinker with your tension.

How do you find the right belt length?

Gates has a calculator on their website that allows you to input both the chainstay length of your frame and the gear ratio you’re looking to achieve. It will then spit out all of the sprocket sizes and belt lengths that will work on your bike.

Do belt drive bikes destroy hub and bottom bracket bearings?

It’s possible that a belted bike with the maximum belt tension could prematurely wear bearings. But on a properly engineered frame, the tension while riding will be similar to using a chain.

Gates Carbon Drive Components

Are there any belt drive manufacturers other than Gates?

Gates has the biggest market share by a huge margin; they claim more than 1000 bike models are fitted with their drivetrains.

You might have seen drivetrains from other manufacturers too, such as Veer, Advanced, Accord, Driveline, or Continental (which is now a discontinued product).

Veer is the most interesting of the lot. They use a split-belt design which means the drivetrain can be retrofitted to any bike with adjustable dropouts. I cannot comment on the performance or reliability, but the Veer sprockets are currently available in just two different gear ratios, which significantly hinders its use.

Advanced claims to operate with less belt tension than other manufacturers thanks to the deeper belt teeth, but there’s almost zero information about them online.

What are the products in the Gates Carbon Drive range?

There are currently four different drivetrains: Sidetrack, CDN, CDC, and CDX. The best way to compare these products is to look at the table in the Gates catalog.

As the products get more expensive, the performance increases as a result of more advanced materials. For example, inside the belts, there are two different compounds for the teeth and three different materials for the carbon tensile cords. The sprockets are made using different types of steel, as well as aluminium, and nylon composite.

The CDX drivetrain offers the most strength, durability, and weather resistance, and can be used on the widest array of bikes.

There are now two different versions:

Regular CDX is what you’ve seen me using on my KOGA WorldTraveller for half a decade. This model uses stainless steel rear sprockets, and either stainless steel or aluminium front sprockets, depending on the number of teeth.

CDX:Black sprockets are brand new this year and are designed to be extra durable. These Chromoly steel sprockets should be better suited to torquey mid-drive electric bikes, and with the new fin tooth design – should shed debris better too.

Are there any known Gates Carbon Drive problems?

In 2015, it was very easy to break the teeth on the first-generation Gates CDN plastic-coated rear sprockets. As a solution, Gates upgraded CDN users to stainless steel sprockets under warranty.

And in 2016, some Rohloff hub belt sprockets developed a creak on the original splined carrier (part #8540). This issue was resolved in 2018 with a new carrier design (part #8540L).

Performance

Why do some belts wear prematurely?

The conditions you cycle in are likely the biggest factor when it comes to component wear. Gritty conditions wear out your sprockets much quicker than clean conditions, so make sure to clean your drivetrain for the best mileage.

High amounts of torque also wear sprockets faster, so expect less distance from high-torque mid-drive e-bikes. If you want, you can reduce the effect of torque on a rear sprocket by pedalling at a higher cadence, or by employing a higher drive ratio.

The rear sprocket size is important too as smaller sprockets have fewer teeth engaged and will, therefore, wear proportionally faster. I get great mileage from my 22-tooth sprockets.

A high belt tension will result in faster wear. This is one reason why you want a dedicated belt drive frame – you can employ a lower tension.

Belt alignment is another key factor. You will wear your sprockets much faster if your belt is not perfectly straight.

Why do belts break?

Belts can break from poor alignment, insufficient tension, or internal cord damage.

If the belt rides up onto the rear sprocket, it can damage both the belt teeth and the internal carbon tensile cords. This situation occurs when there’s insufficient tension, the rear sprocket is loose on your hub, or there’s poor alignment between sprockets.

A product called a ‘belt snubber’ should ideally be fitted to all belt drive bikes. These guide wheels make it impossible for your belt to lift up onto the rear sprocket teeth.

Belts can also be damaged before they’re even fitted to your bike – twisting, back-bending, or crimping belts can damage the carbon cords.

Ryan Van Duzer made a video about how his user error caused a belt to snap. He ‘rolled’ his belt onto the rear sprocket, damaging the internal cords. The lesson learned is that if your belt comes off, take your wheel out, put the belt on the sprocket, and then refit your wheel.

Are chains or belts more efficient?

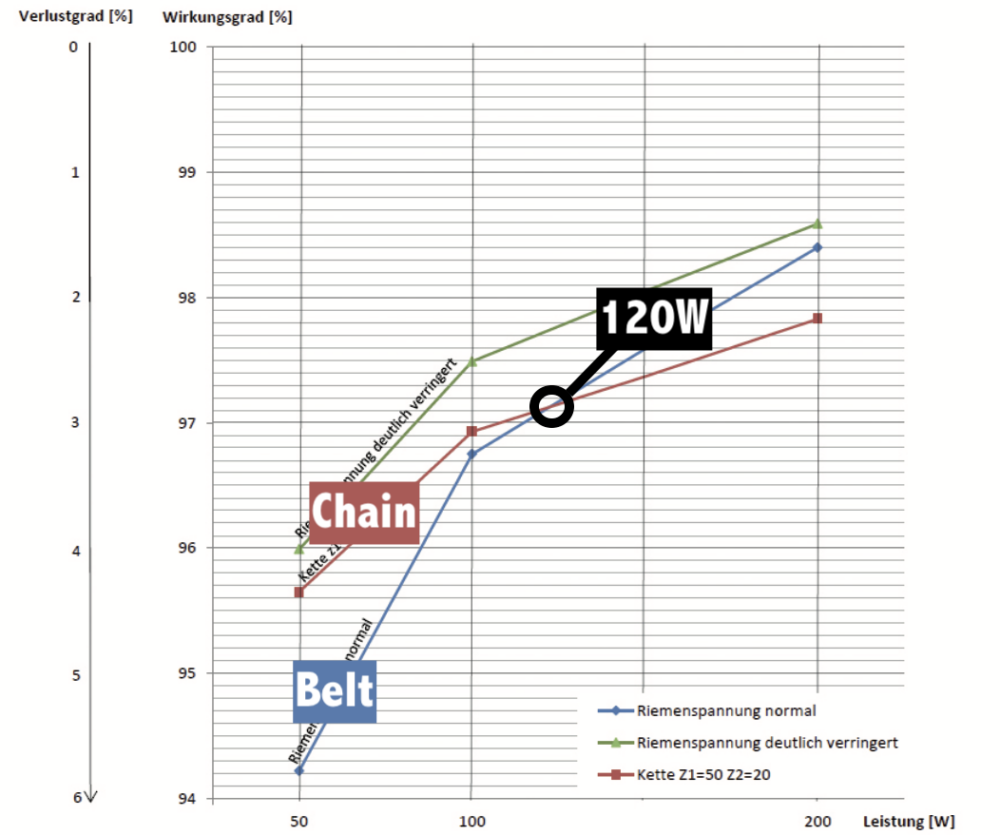

Belt drive is just as efficient as chain drive, but can be more or less efficient depending on the scenario.

I’m going to get a bit nerdy here, but just know that the small differences in drive efficiency across all these scenarios result in virtually no difference in your riding speed.

It’s the gearbox or internal gear hub that’s paired with the belt drive that results in the greatest efficiency losses, usually somewhere between 2 and 6%, or slower riding speeds of 0.25 to 0.75km/h*. This is in perfect lab conditions; expect the difference in drive efficiency to narrow when the riding conditions are muddy or gritty.

*Calculated on BikeCalculator using an 80kg rider, 15kg bike+gear, flat road, 200-watt power output

With that preamble out of the way, some have suggested that belt drive is less efficient than chain drive because when you spin the cranks with your hands, you can feel some resistance. But this test doesn’t tell the full story.

According to data collected from three different lab tests, belts do have an inferior drive efficiency at low power outputs. This is because a belt is always under tension, whereas a chain can run with some slack. As we introduce more pedal or electric power into a drivetrain, a belt soon becomes just as efficient as a chain.

The Trier University lab test (independent) suggests the crossover point is at 120-watts power output, while the Friction Facts lab test (independent) suggests it’s up over 200-watts. And Universal Transmissions (non-independent) found the crossover to be at just 30-watts. Either way, most cyclists will hit these crossover points.

Universal Transmissions (or UT) has recently published some additional belt and chain data that’s worth discussing.

Please note that UT developed the original belt drivetrain in partnership with Gates, and they are also the distributor for Gates Carbon Drive in Europe. As a result, we should remain skeptical of the chain efficiency, resistance, and wear rate data – as these numbers can vary significantly between chain models and lubricants used.

Alright, let’s get onto the interesting findings.

The first is with regard to the drive efficiency on worn chains and belts.

The data suggest that worn belts run more efficiently than worn chains after both 5,000km (100% wear) and 10,000km (200% wear). In fact, the belt at 10,000km was running more efficiently than the chain at 5,000km. This is simply because the chain gets longer over time and can no longer mesh as well with the sprockets.

How about if we use a new chain with the 5,000km old sprockets? That’s also less efficient than a belt after the same distance.

But note that you’ll go through multiple chains over the lifespan of one belt. This means the efficiency of a belt drivetrain continually reduces over time, while the chain will jump between 96% and 98% depending on how worn it is.

The other interesting test was regarding belt drive efficiency at low, medium, and high tensions. This test shows that low tension is best at most power outputs, but by 50 watts, all belt tensions are within 1% – suggesting tension plays a minor role in cycling speed.

Are belt drive bikes worth it?

If you’ve made it to the end here, I think you deserve an honorary Ph.D. in belt drive. Congratulations!

Many world bike travellers have now demonstrated (in the worst riding conditions possible) that belt drive bikes are long-lasting, strong, and low maintenance.

If you prioritise durability and ease of use over everything else, belt drive is the best drive option available. I recommend belts for touring, commuting, bikepacking, cargo hauling, and recreational riding, in particular.

However, belts are not the best for every application. If you want the fastest and lightest bike, you will still be best served by chains and derailleurs.

To learn more about gearboxes, check out my articles on affordable Shimano internal gear hubs, as well as Rohloff hubs, Pinion gearboxes, and Effigear gearboxes. There are also a bunch of new gearboxes coming in for 2023.